Smarter

Stronger

Sustainable

Meet Basalt

International

The world's first vertically-integrated basalt composite company

- On a mission to champion basalt composite solutions around the globe

- The world’s foremost experts in basalt have come together to impact the industry

- Breakthrough projects and products are in the market, with many more to come

Discover the

“Miracle Material”

4-5x lighter than steel for the same strength

Less expensive than galvanized, aluminum, and carbon fiber

Chemically inert, non-conductive, and non-absorbent

Will never rust or corrode like steel

Natural, non-toxic insulator that’s 100% recyclable

Service life of 100+ years

Explore

Revolutionary

Products

Rebar

Basalt fiber reinforced polymer rebar (BFRP) is made from basalt roving

4-6× lighter than steel

30% improvement to concrete EPD

- Relatively heavy material weighs down structures

- Steel rusts, causing corrosion within concrete

- Steel conducts electricity and does not insulate

- Steel rebar has a life of only 30 to 50 years

- Does not benefit Environmental Product Declarations (EPD)

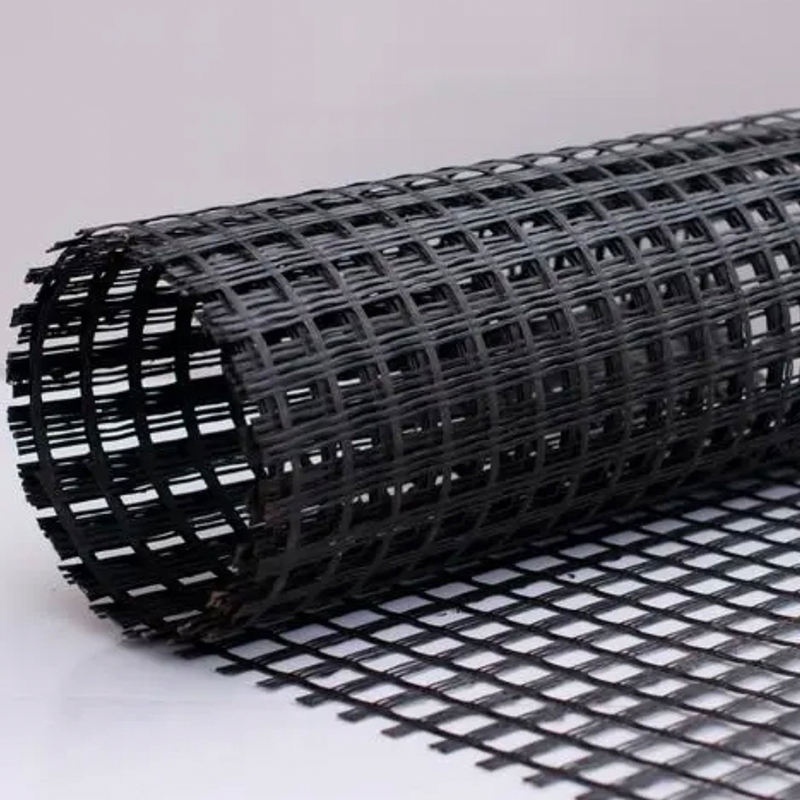

Mesh

Basalt grid, or mesh, is made up of basalt fibers that cross at right angles

5x more resilient than glass fibers

100% environmentally safe

- Basalt rovings are placed freely atop one another

- Arranged in a grid and stitched together with polyester or nylon thread

- Manufactured using chain stitches on knitting machines

- Remarkable resistance to chemically aggressive substances

- Superior tensile strength and durability for ground and structure support

Macrofiber

Basalt Macrofibers are a high-performance fiber-reinforced polymer (FRP) composite

- Based on basalt fiber

- Engineered to provide high post-cracking strength to concrete

- Also increases toughness, impact-resistance, and fatigue-resistance

- Basalt “minibar” macrofiber can be used as primary or secondary reinforcement

- Shipped by container, in palletized 20lb boxes; certified and with EPD

Microfiber

Basalt Chopped Fiber / Microfiber is a short fiber additive for thermoplastics & cement

- Additive for thermoplastics, concrete, asphalt, and cement or gypsum-based mixtures

- Reinforcing agent for plasters, grout, tile adhesives, screeds, and bases

- Reduces cracking and minimizes chipping on product edges

- Significantly enhances appearance and surface finish quality

- Available with a variety of coatings; broad resin compatibility

Bridge Systems

Custom-Engineered Bridge Systems (Composite Bridge Systems)

100% Custom design for each project

15-50% Rise/span of single-radius arches

- Made from durable, corrosion-resistant fiberglass, basalt and carbon fiber composite

- Lightweight for easy transportation, handling, and rapid installation

- Ideal for commercial DOT, infrastructure, parks, trails, and remote access

- Low long-term costs

Sea Wall

Custom-Engineered Sea Walls

100% custom design for each project

- Made from abundant, naturally occurring basalt rock—non-toxic, non-corrosive, and fully recyclable

- Resilient: Exceptionally strong and saltwater-resistant, with a lifespan that exceeds conventional materials

- Adaptable: Customizable to meet the specific needs of diverse coastlines, from urban harbors to rural shorelines

- Carbon-Conscious: Significantly lower embodied carbon footprint than conventional sea wall materials, contributing to climate resilience efforts

Utility Poles

High Performance, Durable Infrastructure

3x stronger than steel

80–100 year lifespan

- High Strength & Lightweight: Basalt fiber poles are up to 3x stronger than steel by weight and significantly lighter than wood or concrete, reducing transportation and installation costs

- Lower Mortality rates upon automobile impact

- Dimensionally stable: Do not warp, bend or twist

- Corrosion & Weather Resistance: Naturally resistant to moisture, UV radiation, chemicals, and extreme temperatures, making them ideal for coastal, humid, or corrosive environments

- Fire & Pest Resistant: Non-combustible and immune to termite, insect, and fungal attacks, eliminating common maintenance concerns.

- Long Service Life: Designed to last 80–100 years with minimal degradation, lowering total lifecycle costs

- Eco-Friendly & Sustainable: The poles are non-toxic and recyclable. Can be made in any color.

- Non-Conductive & Electromagnetically Neutral: Safe for electrical applications with no interference to signals or induced currents

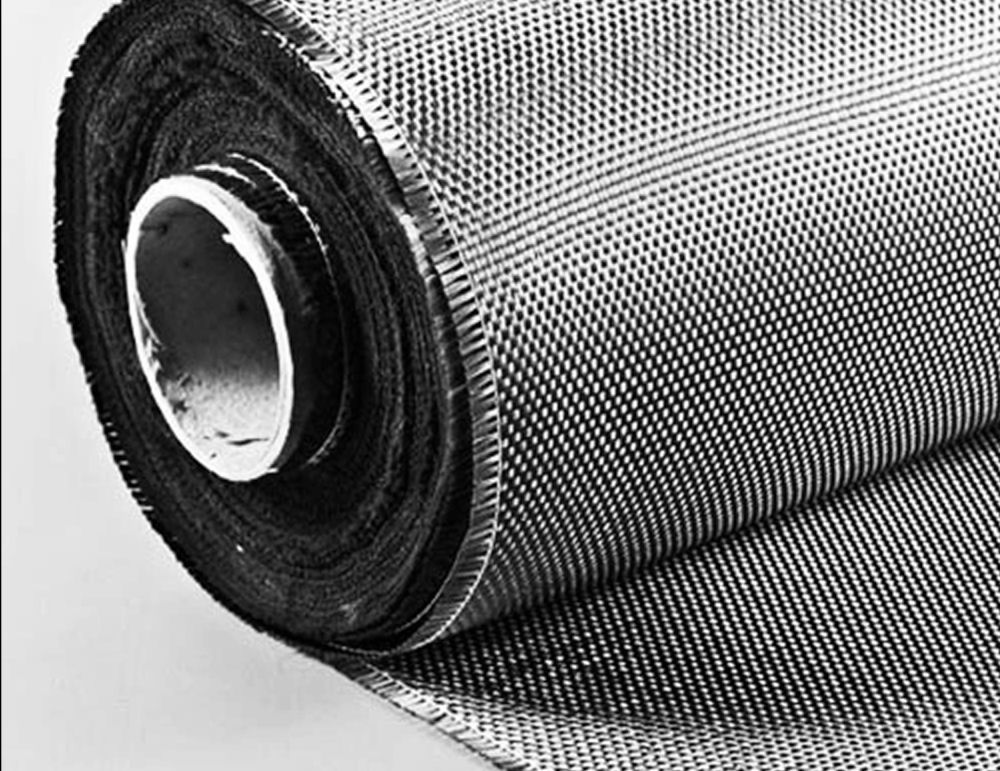

Fabric

Basalt fabric is a high-performance textile made from continuous basalt fiber.

100% Made from natural volcanic rock

- High Thermal Resistance: Withstands temperatures up to 1,000°C (1,832°F) without melting or emitting toxic fumes

- Exceptional Strength-to-Weight Ratio: Offers superior tensile strength while remaining lightweight and flexible

- Corrosion and Chemical Resistant: Performs reliably in harsh environments, including marine and chemical settings

- Eco-Friendly: Made from abundant basalt rock with minimal environmental impact and no additives

- Flame Retardant & Non-Combustible: Ideal for fire protection applications

- Acoustic and Thermal Insulation: Provides excellent insulating properties for construction and industrial use

Leverage Our Expert Services

Basalt International offers world-class design and engineering services to support your projects.

Unmatched knowledge of basalt, structural integrity, and regulations

Tech developed at the Advanced Structures and Composites Center

Examples of completed projects across the U.S., from coast to coast

Trust the Testimonials

Stronger and Lighter, Naturally

"Composite materials like fiber-reinforced polymer (FRP) rebars offer higher tensile strength than Grade 60 steel at just a quarter of the weight—and unlike steel, they don’t corrode. This leads to longer service life for concrete structures. Among the various fibers used in FRP bars, basalt fiber stands out as a naturally sourced and sustainable alternative."

Alvaro Ruiz Emparanza

Ph.D., P.E.; Founder & CEO, Ecotori, LLC

Streamlined Our Process

"Using basalt rebar streamlined our tilt-up wall construction process, offering exceptional ease of use compared to steel rebar. Its lighter weight, easy handling, and resistance to corrosion have translated into substantial labor savings, allowing us to achieve efficiency without compromising on structural strength."

Brian Pratt

COO, McGarvey Development Company

Stronger And More Durable

"BFRP rebar is stronger and more durable than the minimum criteria set for GFRP bars and appears to be a viable alternative as a non-corrosive rebar option."

Steven Nolan

Office of Materials, Florida Department of Transportation

Faster, Stronger, and Longer Life

"The benefits of this bridge-building method are threefold. First, the arches are an instant framework. Second, you don’t need any steel reinforcing bars or rebar, because the arches are twice as strong as steel. And third, the tubes protect the concrete from water and elements, extending the life of the concrete."

Dr. Habib Dagher

Advanced Structures and Composites Center, U. of Maine

Same Building Method

"Whenever you introduce a new technology like this, contractors don’t always jump on it because there’s a fear that it’s going to be difficult to build. One of the beauties of [our composite bridge system] is that it’s built exactly the same way as you would build a steel girder or a concrete girder bridge."

Bill Davids

Chair of Civil and Environmental Department, University of Maine

Lighter Means Faster

"A lot of our time-saving activities once we got to the superstructure were absolutely governed by the weight of the girders themselves and the ability to do more things at once"

Brian Emmons

Project Manager, T Buck Construction

Expertise and Experience Drive Innovation

"It’s a combination of people who know how to build things, how to design things in the real world, plus our knowledge at the University in composite materials. Putting all that together really helped us develop the very unique secret sauce that I think will change how composites will be built in the future."

Dr. Habib Dagher

Advanced Structures and Composites Center, U. of Maine

Faster Than Expected and No Issues

"Even though we knew this would be erected really quickly out in the field, the speed surprised us. It didn’t take very long for them to get their tubes in place, to get all the decking in place and start the backfill process. When you walk into a brand-new product like this, there is a certain level of risk. But there were just no issues at all with the construction."

Mark Gaines

Washington State DOT Bridge & Structures Engineer